Flatlock Stitching: 2025 Review of Top Fitness Wear

Anúncios

Flatlock stitching significantly enhances the comfort, durability, and performance of fitness wear by creating smooth, strong seams that prevent chafing and withstand rigorous activity.

Anúncios

In the dynamic world of athletic apparel, every detail matters. This 2025 review focuses on the impact of seams: a 2025 review of flatlock stitching in 3 leading fitness wear brands, a crucial element often overlooked but vital for performance and comfort. We will explore how this specialized stitching technique elevates the wearer’s experience.

Understanding flatlock stitching

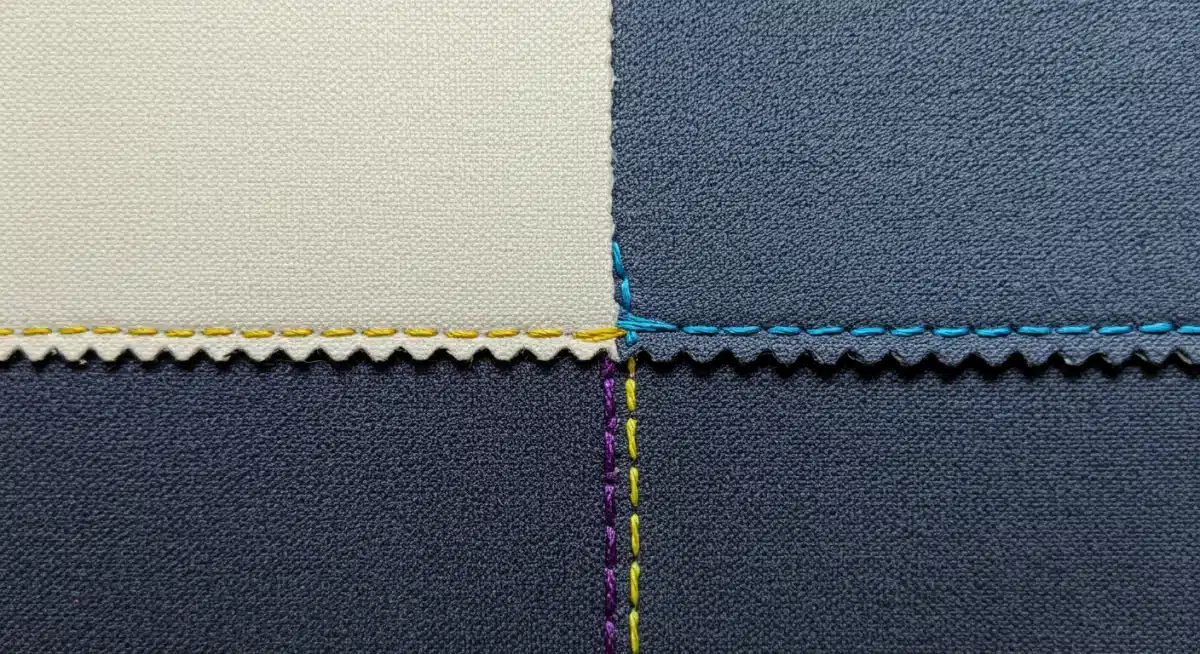

Flatlock stitching is a technique where two pieces of fabric are brought together edge-to-edge, and the stitch is sewn over the raw edges, creating a seam that lies completely flat against the fabric. This method is distinct from traditional overlock seams, which often create a raised ridge.

Anúncios

The primary advantage of flatlock stitching in fitness wear is its ability to eliminate bulk and reduce friction. For athletes and fitness enthusiasts, chafing is a common issue, and flatlock seams are specifically designed to combat this by presenting a smooth surface against the skin. This contributes significantly to overall comfort during prolonged periods of activity.

The mechanics of flatlock seams

Flatlock machines use multiple needles and loopers to interlace threads in a specific pattern. The result is a robust and flexible seam that can stretch with the fabric without breaking or puckering. This elasticity is crucial for performance wear, as it allows garments to move freely with the body.

- Strength: Flatlock seams are incredibly durable, capable of withstanding the stresses of high-intensity workouts and frequent washing.

- Flexibility: They stretch in harmony with the garment’s fabric, preventing restrictive feelings.

- Aesthetics: The clean, flat appearance also adds to the garment’s visual appeal, often used as a design element.

In essence, flatlock stitching is not merely a method of joining fabrics; it’s a performance-enhancing feature. Its smooth profile minimizes skin irritation, while its inherent strength ensures longevity, making it an indispensable technique in modern fitness apparel manufacturing.

The evolution of fitness wear seams

The journey of fitness wear has seen significant advancements, particularly in seam technology. Historically, athletic garments relied on conventional sewing methods that often resulted in bulky, irritating seams. These earlier techniques, while functional, frequently compromised comfort and, consequently, performance.

As consumer demands for high-performance apparel grew, manufacturers began exploring innovative solutions. The shift towards synthetic, stretchable fabrics necessitated seam technologies that could match the material’s elasticity and recovery properties. This era marked a crucial turning point, leading to the widespread adoption of specialized stitching methods.

From basic to advanced: a timeline

Early athletic wear often featured simple lockstitch or overlock seams. While economical, these seams could be abrasive, especially under repetitive movement and moisture. The introduction of flatlock stitching represented a significant leap forward, directly addressing these discomfort issues.

- 1970s-1980s: Predominantly use of basic overlock seams, leading to chafing complaints.

- 1990s: Emergence of technical fabrics and a growing awareness of seam impact on performance.

- 2000s-Present: Widespread adoption of flatlock and other advanced seam constructions as industry standards.

The evolution wasn’t just about comfort; it was also about garment integrity. Athletes push their gear to the limits, and seams are often the weakest point. Flatlock stitching offers a higher degree of seam strength and integrity, reducing the likelihood of unraveling or tearing during strenuous activities. This continuous improvement in seam technology underscores the industry’s commitment to enhancing athletic performance and wearer satisfaction.

Brand spotlight: Nike’s approach to flatlock

Nike, a global leader in athletic apparel, consistently integrates advanced seam technologies, with flatlock stitching being a cornerstone of many of its performance lines. The brand’s commitment to innovation is evident in how it leverages flatlock seams to enhance athlete comfort and movement.

For Nike, flatlock stitching is more than just a functional detail; it’s an integral part of their design philosophy aimed at creating a near-seamless feel. This design choice is particularly crucial in garments like running tights, base layers, and compression wear, where fabric-to-skin contact is constant and extensive.

Nike’s specific applications and benefits

Nike often employs flatlock stitching in areas prone to friction, such as inner thigh seams, shoulder seams, and along the sides of torso garments. This strategic placement ensures maximum comfort where it’s needed most.

- Dri-FIT Technology: Flatlock seams complement Nike’s moisture-wicking fabrics by maintaining a smooth interior, preventing irritation as sweat is drawn away from the body.

- Compression Fit: In compression garments, the flatlock stitch allows for superior stretch and recovery, ensuring the garment retains its shape and supportive properties over time.

- Minimizing Distraction: By eliminating bulky seams, Nike helps athletes focus on their performance, free from the distraction of uncomfortable rubbing.

Nike’s extensive research and development into fabric and construction techniques ensure that their flatlock seams are not only durable but also contribute to the overall aerodynamic and ergonomic design of their apparel. This meticulous attention to detail solidifies Nike’s reputation for high-quality, performance-driven fitness wear.

Brand spotlight: Lululemon’s precision seams

Lululemon has built its brand on a foundation of premium quality and exceptional comfort, and flatlock stitching plays a pivotal role in achieving this reputation. Known for its yoga and activewear, Lululemon places a high emphasis on the feel of the fabric against the skin, making flatlock seams a natural fit for their product line.

The brand’s dedication to creating a “second-skin” experience is largely facilitated by the smooth, non-intrusive nature of flatlock stitching. This is particularly important for activities like yoga and pilates, where a full range of motion and an uninterrupted connection with the body are paramount.

Lululemon’s design and material synergy

Lululemon frequently pairs its proprietary fabrics, such as Luon and Nulu, with flatlock stitching to maximize their inherent properties. These fabrics are renowned for their softness, stretch, and moisture-wicking capabilities, all of which are enhanced by the seamless feel of flatlock construction.

- Enhanced Comfort: The flat profile of the seams prevents any digging or rubbing, even during complex poses or movements.

- Durability: Despite their delicate feel, Lululemon’s flatlock seams are engineered for longevity, resisting wear and tear from frequent use and washing.

- Streamlined Look: The clean lines created by flatlock stitching contribute to the sleek and sophisticated aesthetic that Lululemon customers appreciate.

Lululemon’s focus on meticulous craftsmanship extends to every seam, ensuring that each garment provides an uncompromised level of comfort and performance. Their strategic use of flatlock stitching reinforces their position as a leader in premium activewear, where form and function seamlessly intertwine.

Brand spotlight: Under Armour’s robust construction

Under Armour, a brand synonymous with performance and innovation, heavily relies on flatlock stitching to deliver durable and comfortable athletic apparel. Their focus on empowering athletes through superior gear means that every component, including seams, must meet rigorous standards.

For Under Armour, flatlock stitching is a critical element in garments designed for high-impact sports, intense training, and extreme conditions. The brand’s commitment to making athletes better is reflected in its choice of construction techniques that can withstand the most demanding environments.

Under Armour’s performance-driven applications

Under Armour frequently utilizes flatlock seams in its compression shirts, cold weather gear, and tactical apparel. These are products where seam integrity and wearer comfort are paramount to performance and safety.

- UA Tech and HeatGear: Flatlock seams are essential in these lines to ensure a smooth, chafe-free experience, allowing the fabrics to perform their moisture-wicking and temperature-regulating functions effectively.

- Compression Benefits: The robust yet flexible nature of flatlock seams enables Under Armour’s compression wear to provide consistent muscle support without restricting movement or causing discomfort.

- Longevity in Tough Conditions: The inherent strength of flatlock stitches contributes to the overall durability of Under Armour garments, making them reliable choices for athletes who train hard and often.

Under Armour’s engineering philosophy dictates that every stitch serves a purpose. By integrating flatlock stitching into their performance apparel, they ensure that their garments not only feel good but also perform under pressure, offering athletes the confidence to push their limits without concern for their gear.

The future of seam technology in fitness wear

As we look beyond 2025, the landscape of fitness wear seam technology continues to evolve. While flatlock stitching remains a gold standard, ongoing research and development aim to push the boundaries even further. The drive for ultimate comfort, performance, and sustainability is shaping the next generation of athletic apparel construction.

Emerging technologies focus on even more advanced methods of joining fabrics, some of which seek to eliminate traditional stitching altogether. Concepts like ultrasonic welding, bonding, and laser fusion are gaining traction, promising truly seamless garments that could offer unparalleled comfort and a sleek aesthetic.

Innovations on the horizon

These cutting-edge techniques offer several potential advantages over conventional stitching, even flatlock. They can create incredibly smooth, lightweight, and durable bonds, further reducing the risk of chafing and enhancing the garment’s overall performance characteristics.

- Ultrasonic Welding: Uses high-frequency acoustic vibrations to create heat and fuse thermoplastic materials, resulting in a strong, flat bond without thread.

- Adhesive Bonding: Employs specialized glues and heat presses to join fabric panels, creating ultra-smooth seams that are virtually invisible.

- Laser Fusion: Utilizes precise laser energy to melt and bond fabric edges, offering clean finishes and high durability.

However, the widespread adoption of these technologies faces challenges, including cost, material compatibility, and scalability. Flatlock stitching, with its proven track record and cost-effectiveness, is likely to remain a dominant force in fitness wear for the foreseeable future, even as these newer methods carve out their niche. The blend of traditional excellence and futuristic innovation will define the next era of athletic apparel seams.

| Key Aspect | Description |

|---|---|

| Chafe Prevention | Flatlock seams lie flat, significantly reducing skin irritation and chafing during physical activity. |

| Durability | These seams offer superior strength and flexibility, resisting wear and tear under strenuous conditions. |

| Brand Adoption | Leading brands like Nike, Lululemon, and Under Armour extensively use flatlock stitching for performance wear. |

| Future Outlook | While new technologies emerge, flatlock remains vital, balancing innovation with proven effectiveness. |

Frequently Asked Questions About Flatlock Stitching

Flatlock stitching joins two fabric edges seamlessly, creating a flat, smooth seam. It’s crucial for fitness wear because it prevents chafing and irritation, enhancing comfort and allowing for unrestricted movement during physical activity. This makes garments more enjoyable to wear for extended periods.

Traditional seams, such as overlock, typically create a raised ridge where fabric edges overlap, which can cause friction against the skin. Flatlock stitching, conversely, interlocks threads over abutted fabric edges, resulting in a seam that lies completely flat and smooth, minimizing bulk and irritation.

Major brands like Nike, Lululemon, and Under Armour extensively use flatlock stitching in their performance apparel. They recognize its benefits for comfort, durability, and a sleek aesthetic, integrating it into their designs to meet the high demands of athletes and fitness enthusiasts.

Yes, flatlock stitching significantly enhances durability. The interlocking thread structure creates a strong, flexible seam that can withstand stretching, repeated stress from movement, and frequent washing without unraveling or breaking. This contributes to the garment’s longevity and structural integrity over time.

Indeed, advancements like ultrasonic welding, adhesive bonding, and laser fusion are emerging. These techniques aim to create even smoother, truly seamless garments by eliminating threads altogether. While growing, flatlock stitching remains a trusted and widely adopted method due to its proven effectiveness and balance of cost and performance.

Conclusion

The 2025 review of flatlock stitching in leading fitness wear brands clearly demonstrates its indispensable role in modern athletic apparel. From Nike’s performance-driven designs to Lululemon’s comfort-focused garments and Under Armour’s robust construction, flatlock seams are a common thread, literally and figuratively. They deliver unparalleled comfort by minimizing chafing, enhance garment durability, and contribute to the sleek aesthetic demanded by today’s active consumers. While newer, seamless technologies are on the horizon, flatlock stitching’s proven effectiveness and widespread adoption ensure its continued prominence, solidifying its status as a critical component in the pursuit of optimal athletic performance and wearer satisfaction.